To keep natural gas in a liquid state, it needs to be stored at a temperature of -163°C during transportation. But, if regular metals are exposed to such low temperatures, they can crack from the cold. That’s why scientists discovered invar steel, a material that has become essential for LNG ships.

Invar steel (also called invar alloy) is a mix of nickel, iron, and a small amount of carbon. This metal has a very low thermal expansion rate, meaning it doesn’t expand or contract much with temperature changes. Because of this, it stays stable even at extreme temperatures, making it perfect for LNG ships.

The hardest part of building an LNG ship is welding invar steel to create a storage tank for natural gas. Invar steel rusts easily, and even a tiny bit of water during the welding process can ruin the entire weld. Welding requires heating the metal to a high temperature, but invar steel’s low thermal expansion means it needs an even higher heat to weld properly.

Before welding, the area is preheated to between 150°C and 250°C, and the workers often work in temperatures above 50°C. Given how hot and heavy it gets, it’s not just a challenge of skill – it’s physically demanding as well.

For an LNG ship with a storage capacity of 14.7 cubic meters, around 130 kilometers of invar steel needs to be welded. This process must be perfect – any mistake could impact the entire ship. What makes this even more difficult is that many of the materials used for welding invar steel are being used for the first time in China, which adds to the challenge.

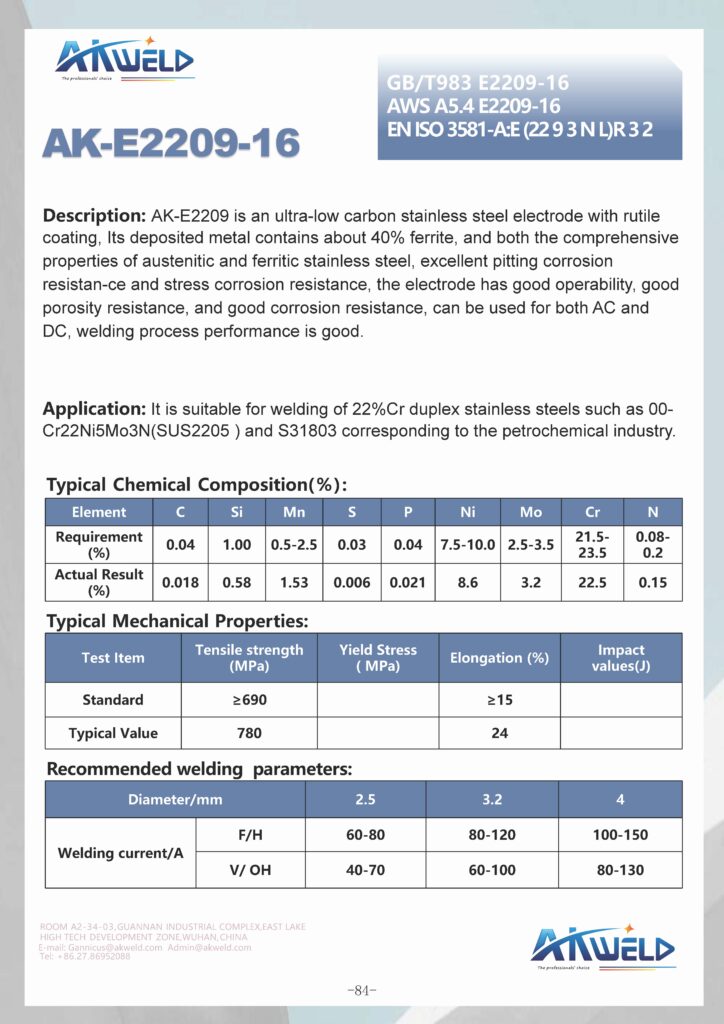

Along with top-notch welding skills, the quality of welding materials is also crucial. Below are some of the welding consumables we provide for critical areas on LNG ships.