Allied Market Research has released a report on the global aluminum welding market size by 2030.

Three points are mentioned:

The report provides forecasts from three perspectives:

1. Classification of welding wire types (pure aluminum welding wire, aluminum-magnesium alloy welding wire, and aluminum-silicon alloy welding wire)

2. Classification by technology (arc welding and gas metal arc welding (MIG), gas tungsten arc welding (TIG), torch welding, laser beam welding, electron beam welding, resistance welding and others)

3. Classification by end use (automotive, aerospace, marine, construction and others)

Three forecasts are given, from now until 2030:

1. Aluminum-magnesium alloy welding wire will dominate the market: This type of welding wire has excellent corrosion resistance, high strength and good weldability, so it is very suitable for use in harsh environments such as ships and automobiles. In the marine industry, where structures are often exposed to salt water and harsh weather conditions, the corrosion resistance of aluminum-magnesium alloys is critical. Similarly, in the automotive industry, these alloys are the material of choice for manufacturing lightweight yet strong automotive components, helping to improve fuel efficiency and reduce emissions. In addition, the high strength-to-weight ratio of aluminum-magnesium alloys makes them suitable for applications that require durable, strong materials without adding excessive weight.

2. The field of gas metal arc (MIG) welding technology will dominate the market: MIG welding is widely used in industries such as automotive and aerospace, which require high precision and productivity. MIG welding produces high-strength, high-quality welds with minimal spatter and post-weld cleaning, making it the preferred manufacturing process.

3. The automotive market will dominate: The automotive industry is the main driving force behind welding technology innovation, and requires advanced technologies such as MIG and TIG welding to achieve precise, high-quality connections. Aluminum is widely used in the manufacture of various automotive parts, including body panels, frames and engine components, highlighting its important role. With the popularity of electric vehicles (EVs), the demand for lightweight materials such as aluminum is expected to surge further, thus consolidating the automotive industry’s dominant position in the aluminum welding market.

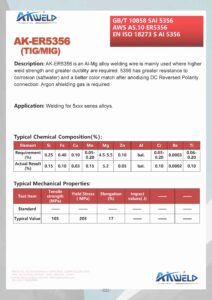

AKWELD provides aluminum-magnesium alloy welding wires, and the following two are commonly used. We provide more than the following two types. If you have more needs and inquiries, please feel free to contact us.

English

English Portuguese

Portuguese Russian

Russian Spanish

Spanish